Pump Manufacturing

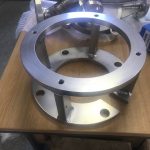

For industrial manufacturing processes, vapour honing can achieve uniform surface finish following fabrication and machining. It can remove marks left by general handling and processes such as welding. These parts fabricated and machined pump assemblies

Cheshire Pump Company Limited Click to view is part of our business. A customer asked us to improve some of the components from high specification pump project using the Vapour Blasting process. The parts are machined and welded

The parts are high grade alloy and stainless steel. Manufacturing had left some marks and discolouring. Following testing with die penetrants and non-destruct testing they were ready for finishing prior to final assembly.

The goal was to achieve a uniform finish across the parts and remove discolouring from welding prior to final assembly, inspection and testing.

Following Vapour Blasting, the customer was very happy with the results and we are expecting to grow our activities with them

Vapour Blasting has the effect of removing any surface oxidation which may be problematic for the treatment of high grade steels and alloys.

Parts made from high grade materials may need pickling or passivation following manufacture. Vapour Blasting enhances this process by removing surface contaminents left during manufacture. Vapour Blasting has the effect of removing any surface oxidation which may be problematic for the treatment of high-grade steels and alloys.